Whether you are looking to use WPC foam board for furniture making, sign making, or any other purpose, you're sure to be pleased with its high strength and versatility. You can even print directly onto the surface, and it is UV coated for weather resistant properties.

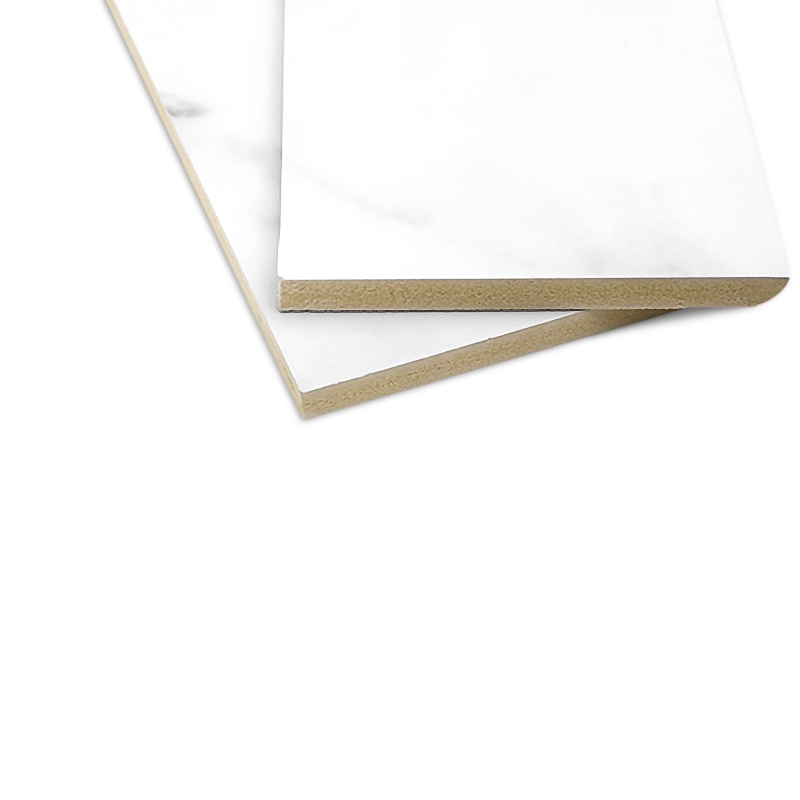

Compared to MDF, WPC foam board has better processing performance and a number of advantages. The board is waterproof, durable, heat and cold resistant, and also flame retardant. It has anti-corrosion properties, making it an excellent replacement for wood. It also has excellent insulation properties. It is suitable for wall lining and ceilings in residential houses.

A number of companies manufacture and supply this product. It is available in various colors, thicknesses, and finishes. It is an ideal replacement for wood and plywood. It is lightweight, strong, and can be easily cut and installed.

It is easy to paint, and is resistant to moisture. It can also be stained or varnished. It is a more affordable alternative to plywood and natural wood.

Using WPC foam board in your home will keep you safe from fire and rot. It's also more durable than wood and will hold up well to harsh weather conditions. It's also a great eco-friendly option.

WPC is made up of wood fibres and thermoplastics, which are extruded into different shapes. Its density is high, making it more durable. It is a fire-retardant material that doesn't emit formaldehyde or odour.

It's also easy to install. It can be trimmed, shaped, drilled and sanded. It has a rich appearance that makes it ideal for exterior and interior applications. It's available in various thicknesses and colours.

Using WPC foam board for furniture making is one of the best solutions that are available today. WPC is an innovative material that is more durable and flexible than PVC boards. Moreover, it is a safe material that is eco-friendly and highly fire-resistant.

It is made from thermoplastics and wood fibers that are extruded into various shapes. These materials are then treated with modern surface treatment to give them a different look. These materials are also very durable and strong.

They are a good choice for interior as well as exterior applications. They are used in wardrobes, home furniture, and office furniture. They are also used in ceiling solutions and wall paneling. Moreover, they are termite proof, fire-retardant, and waterproof. They are a cost-effective replacement for plywood. They are also available in a variety of shapes and sizes.

It doesn't need a compulsory lamination

Unlike wood, PVC foam boards do not decay and are highly resistant to corrosive agents. They are also moisture resistant. They are commonly used in furniture, outdoor deck flooring, and indoor applications.

PVC foam board is a flexible material, which is shaped into different shapes. The material is usually used in building and advertising industries. It is light in weight and easy to handle.

The PVC foam board can be cut, laminated, drilled, screwed, and embossed. It is also resistant to fungus, mildew, and common corrosives. It is durable, easy to clean, and provides excellent noise insulation. It is suitable for indoor applications such as furniture and cabinets, and outdoor applications such as fencing and wall panels.

Using WPC foam board in your home is a great idea if you have a fire prone environment. The material is fire retardant and if the fire is confined to a single room, it will be extinguished without a fuss. Moreover, WPC is lightweight, and can be used in outdoor applications such as decks and fences. It is also an eco-friendly material that does not produce any visible defects when exposed to sunlight.

WPC foam board is also good for smaller scale applications like countertops, window frames, door frames, and even ceiling tiles. It can be used in a variety of applications ranging from the home to the office. WPC is not only lightweight, but is also moisture resistant.

It can be directly printed and UV coated

Using UV coating on foam board gives better protection for its surface and improves its life. WPC foam boards can be used for surface decoration and for surface beautification. This makes it ideal as a substrate for furniture and display boards.

English

English Español

Español