1. Exhibition cabinet, shelf in supermarket 2. Advertisement Board and Sign Board 3. The advertiseme...

Web Menu

Product Search

Exit Menu

PDF Download

How Can We Help You ?

We reaffirm the high quality service of "high quality, low cost", "integrity builds character, dedication to create quality" as the company's pursuit!

+86 13336092708 Contact UsPVC Foam Board Manufacturer

-

1220*2440mm Marble sheet UV coating pvc laminated board

-

17mm white color hard surface Cabinet PVC foam board

-

17mm 4*8 feet Furniture/Adertisement PVC foam fheet

-

Flexible cabinet and interior 17mm PVC plastic sheets

-

Factory directl PVC board for decorative panel

-

Closed cell waterproof reinforced PVC foam board

-

24mm PVC celuka board PVC foam sheet for wall partition and doors

-

CNC engraving 5mm 8mm PVC sheet for decoration

-

Waterproof 12-18mm PVC foam board for furniture

-

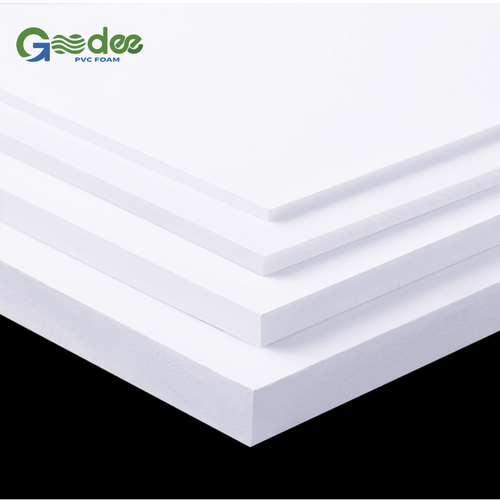

Pvc Foam Board

-

Pvc Foam Board

-

Pvc Foam Board

-

17mm white color hard surface Cabinet PVC foam board

Read MoreApplication of our PVC foam board: PVC foam board can be used in Bathroom Cabinet/Kitchen Cabinet/De...

-

17mm 4*8 feet Furniture/Adertisement PVC foam fheet

Read MorePVC foam board has been widely popular in advertising, construction, home furnishing, decoration, an...

-

Flexible cabinet and interior 17mm PVC plastic sheets

Read MoreThese high density PVC rigid boards have become substitution of wood in many fields. Pluswin PVC Foa...

-

Factory directl PVC board for decorative panel

Read MoreApplication Used in interior panels, decorative panels, building wall panels Used in cabinets...

-

Closed cell waterproof reinforced PVC foam board

Read MoreApplication 1. Interior decoration: Inner decoration: bus, car, train, boat ... ; Bed panel, ca...

-

24mm PVC celuka board PVC foam sheet for wall partition and doors

Read MoreApplication of PVC Celuka Foam Board: It can be used as plain white color,no need to be painted,also...

-

CNC engraving 5mm 8mm PVC sheet for decoration

Read MoreApplication 1.Exhibition cabinet, shelf in supermarket 2.Advertisement Board and Sign Board 3.The ad...

-

Waterproof 12-18mm PVC foam board for furniture

Read MoreApplication PVC foam boards can be used in interior applications, exterior applications and for adve...

English

English Español

Español