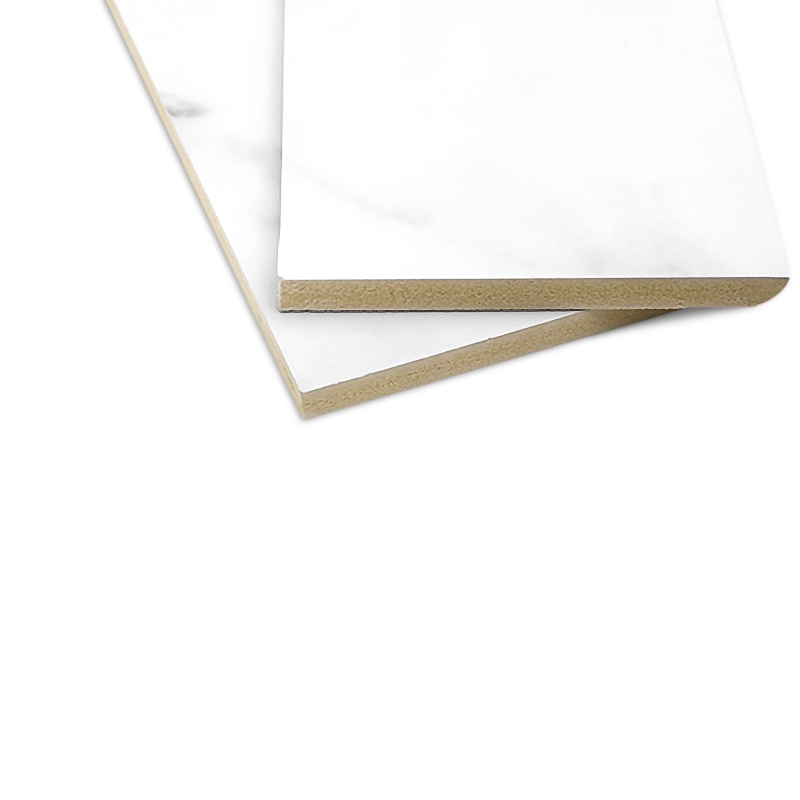

When it comes to CNC engraving on PVC sheets, there are two standard thicknesses commonly used - 5mm and 8mm. These thicknesses provide a good balance between durability and affordability, and can be engraved with intricate designs using a CNC machine. The process involves using a cutting tool, such as a router or laser, to carve out the design from the surface of the PVC sheet.

Before starting the engraving process, it's important to select the right type of PVC sheet for the job. There are different grades of PVC sheets, each with its own unique properties. For CNC engraving, a high-quality, rigid PVC sheet is recommended. This type of PVC has a smooth surface, is strong and durable, and provides excellent results when engraved.

Once the right type of PVC sheet has been selected, the next step is to prepare the design that will be engraved. This can be done using computer-aided design (CAD) software, such as AutoCAD or Illustrator. The design can be as simple or as complex as desired, and can include text, graphics, and images. Once the design is complete, it is loaded into the CNC machine, which uses software to control the cutting tool and create the final product.

When it comes to CNC engraving on PVC sheets, there are two main cutting methods: routing and laser engraving. Routing involves using a rotating tool to carve out the design from the surface of the PVC sheet. This method is ideal for creating detailed designs, and is especially good for cutting intricate shapes. Laser engraving, on the other hand, uses a high-powered laser beam to vaporize the material, leaving a precise, detailed engraving. Laser engraving is best for fine details and precise lines, and can also produce a smooth surface that is ideal for painting or other treatments.

One of the biggest benefits of CNC engraving on PVC sheets is the ability to produce consistent results every time. The CNC machine uses precise measurements and computer control to create an accurate and consistent engraving, without the risk of human error. Additionally, the CNC machine can work 24/7, allowing for high production rates and fast turnaround times.

Another advantage of CNC engraving on PVC sheets is the ability to create custom designs. Whether it's a logo, a company name, or a unique design, the CNC machine can create it. This makes CNC engraving on PVC sheets ideal for creating unique and personalized products, such as custom awards, signs, and plaques.

In conclusion, CNC engraving 5mm 8mm PVC sheet for decoration is a popular and versatile method for producing decorative items. The process is fast, accurate, and cost-effective, and allows for the creation of custom designs. Whether it's a sign, plaque, or award, CNC engraving on PVC sheets is a great choice for creating high-quality decorative products that are both beautiful and durable.

English

English Español

Español