Aluminium foam board, additionally referred to as aluminium foam composite panel, is a exceedingly new cloth that has received reputation in the construction and production industries due to its particular residences and blessings. In this text, we are able to examine aluminium foam board to traditional materials used in production and production, including wood, metallic, and concrete, highlighting its advantages and potential applications.

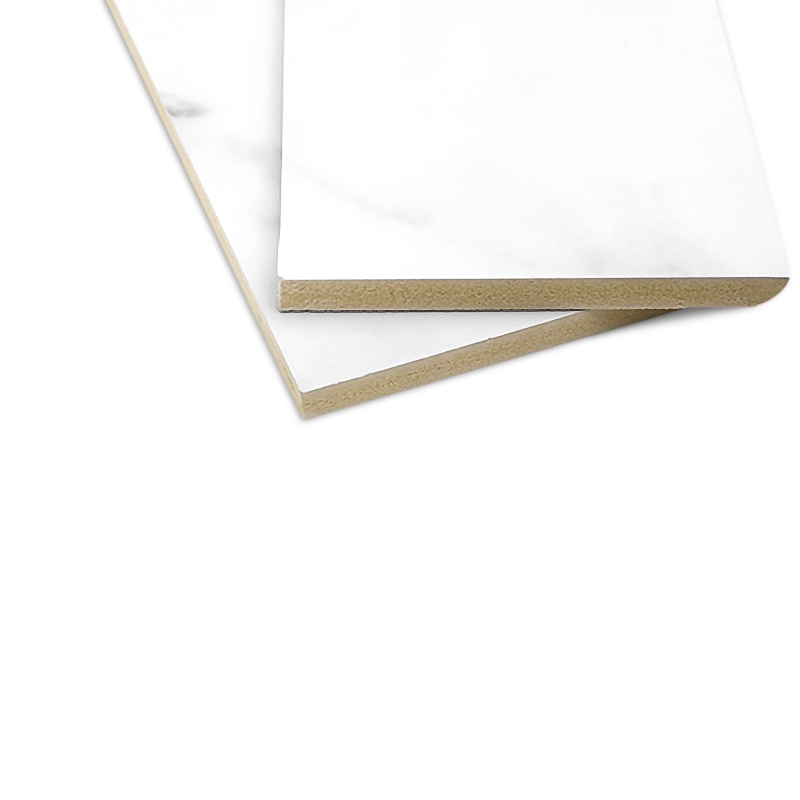

1. Weight and density:

Aluminium foam board is exceptionally light-weight compared to standard materials. With a density starting from 0.Four to 0.Eight g/cm3, it's far tons lighter than wood (zero.5-zero.8 g/cm3), metal (7.8 g/cm3), and urban (2.Three-2.Five g/cm3). The low density of aluminium foam board makes it simpler to address, delivery, and set up, reducing related expenses and labor requirements. Additionally, the lightweight nature of the cloth lets in for faster production strategies, as panels can be effortlessly assembled and maneuvered into area.

2. Strength and durability:

Despite its light-weight, aluminium foam board exhibits excellent power and durability. The aggregate of aluminium and foam creates a composite material this is more potent than pure metallic and foam on my own. The presence of aluminium inside the foam matrix gives structural integrity, at the same time as the foam cells distribute and take in pressure, stopping localized failure. Compared to timber, steel, and concrete, aluminium foam board has a higher power-to-weight ratio and can face up to big hundreds with out deformation or failure. This makes it appropriate for light-weight structural components, inclusive of walls, façade panels, and roofing systems.

Three. Thermal insulation:

Aluminium foam board possesses terrific thermal insulation residences because of the presence of foam cells inside its shape. The foam acts as a barrier, reducing heat transfer through conduction and minimizing thermal bridging. This insulation capability is superior to standard substances like wood, metallic, and urban, which might be conductive and offer minimal to no insulation. The thermal resistance of aluminium foam board allows preserve a snug indoor environment by using decreasing the reliance on heating and cooling systems, resulting in strength savings and reduced carbon emissions.

4. Sound insulation:

In addition to thermal insulation, aluminium foam board gives terrific sound insulation homes. The cells within the material act as acoustic obstacles, soaking up and dampening sound waves, resulting in reduced noise transmission. This it an wonderful desire for programs which include acoustic wall panels, soundproof walls, and flooring systems. Compared to substances like wooden, metallic, and urban, that are sound conductive, aluminium foam board offers advanced sound insulation abilties, contributing to quieter and more comfortable dwelling or operating surroundings.

Five. Fire resistance:

One of the important thing advantages of aluminium foam board is its excellent fireplace resistance. The presence of aluminium within the foam matrix presents inherent hearth retardant homes. Aluminium has a excessive point (660°C) and does no longer burn, protective the foam shape from direct exposure to flame. This makes aluminium foam board especially proof against fire and inhibits the spread of fireplace in case of a scourge. In assessment, traditional materials like, metallic, and urban are flammable and may contribute to fire propagation. The fire-resistant nature of aluminium foam board guarantees more advantageous protection in production and manufacturing packages.

6. Corrosion resistance:

Aluminium foam board well-knownshows superior corrosion resistance as compared to conventional substances like timber and metal. Wood is vulnerable to rot, decay, and insect harm, requiring ordinary maintenance and. Steel is liable to rust and corrosion, necessitating defensive coatings and regular inspections. In contrast, aluminium foam board is affected by moisture, humidity, or insect infestations, making it a pretty long lasting and lengthy-lasting cloth. This corrosion resistance makes aluminium foam board appropriate for various indoor and out of doors packages, along with cladding, roofing, and marine production.

7 Design flexibility and customization:

Aluminium foam board gives top notch layout flexibility and customization alternatives. The cloth can be without problems cut, fashioned, and shaped into various styles and sizes to fulfill particular undertaking requirements. It also can be bonded or laminated with different materials to beautify its homes or acquire particular aesthetic effects. Unlike conventional materials that often require specialized gear or strategies for personalisation, aluminium foam board may be without difficulty fabricated the use of preferred woodworking gear, adding cost to production procedures.

In conclusion, aluminium foam board is a flexible and revolutionary fabric that outperforms conventional production and production materials in several factors. Its lightweight, high electricity, thermal and sound insulation houses, hearth resistance, corrosion resistance, and layout flexibility make it a compelling choice for a variety of applications. While traditional materials like timber, steel, and urban continue to have their very own advantages and packages, the particular homes of aluminium foam board make it a promising material for the destiny of production and production.

English

English Español

Español