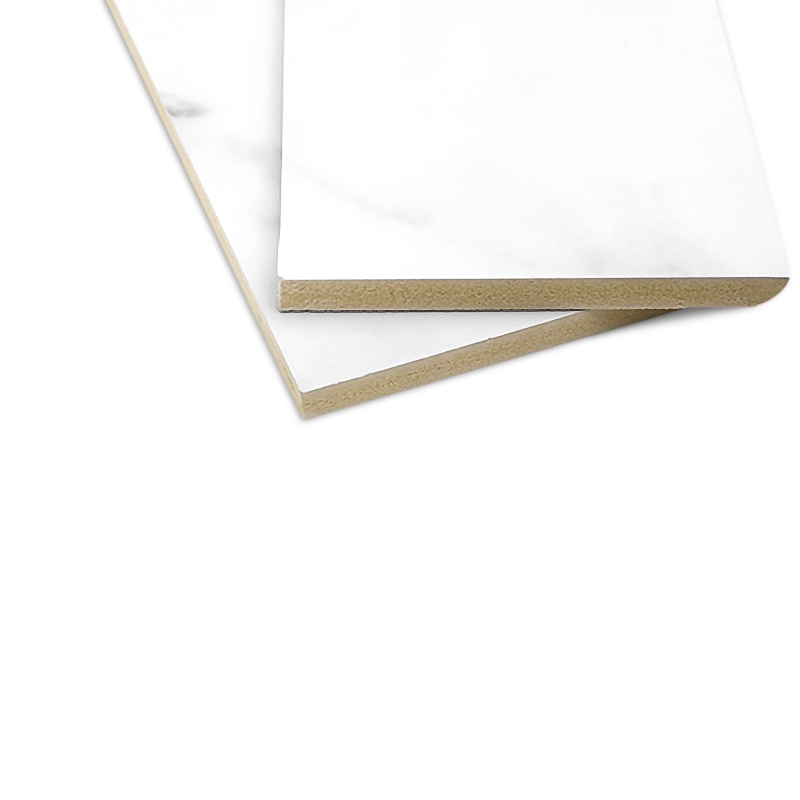

The weight of aluminum foam boards is significantly lower than that of solid aluminum or many other traditional materials used in construction and manufacturing. Aluminum foam is a lightweight cellular material with a structure that resembles a sponge or honeycomb, made up of gas-filled pores surrounded by a solid aluminum matrix.

The density of solid aluminum is about 2.7 grams per cubic centimeter (g/cm³), whereas aluminum foam typically has a density range of 0.2 to 1.0 g/cm³, depending on the manufacturing process and specific application. This means that aluminum foam can be up to 10 times lighter than solid aluminum.

Comparing aluminum foam to other common materials:

Steel: The density of steel is around 7.8 g/cm³, making aluminum foam about 7 to 39 times lighter than steel, depending on the specific aluminum foam density used.

Concrete: The density of concrete can vary, but it generally ranges from 2.3 to 2.5 g/cm³, making aluminum foam about 2 to 12 times lighter.

Wood: Wood's density varies depending on the type of wood, but it generally falls between 0.3 to 0.9 g/cm³, making aluminum foam similar in weight or slightly lighter.

Plastics: The density of plastics can vary widely, but most fall in the range of 0.9 to 1.5 g/cm³. Aluminum foam is generally lighter than most plastics, though there might be some plastics that are lighter depending on their specific composition.

Due to its lightweight nature, aluminum foam is highly advantageous in applications where weight reduction is essential, such as in aerospace, automotive, and marine industries. It offers the potential to save weight without compromising on mechanical properties, making it an attractive material for various engineering applications.

English

English Español

Español