PVC boards are made from a thermoplastic polymer called Polyvinyl Chloride. They are formed by blending PVC resin with other additives and extruding them into flat sheets. These sheets can then be cut, routed, and fabricated into various shapes and sizes.

PVC boards are commonly used for a range of applications, including signboards, furniture, wall cladding, and ceiling panels. They come in different grades, colors, and finishes, making them suitable for different environments and purposes.

Factory-direct PVC boards for decorative panels are those that are produced and sold by the manufacturer without any intermediaries. They are made to order and customized to meet the customer's specific requirements, ensuring that they get the exact product they need.

One of the benefits of factory-direct PVC boards is that they are typically cheaper than purchasing from a distributor or retailer. This is because there are no middlemen involved, and the manufacturer can pass on the savings to the customer. Additionally, factory-direct PVC boards are often of higher quality than those sold through intermediaries since the manufacturer has full control over the production process.

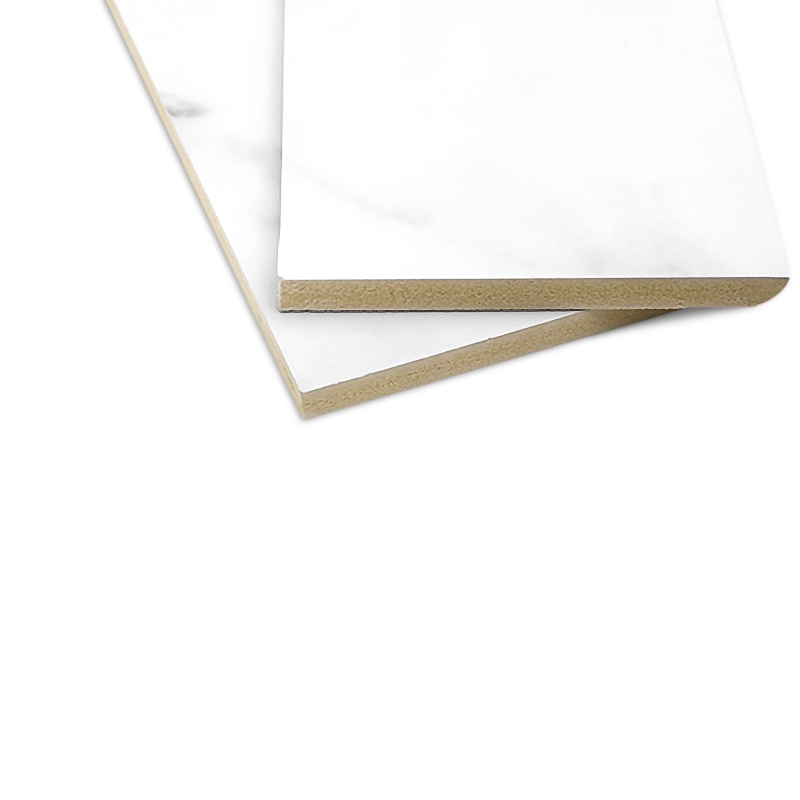

PVC boards for decorative panels come in various thicknesses, from 1mm to 25mm, and sizes ranging from 1220mm x 2440mm to 1560mm x 3050mm. They can be cut to any size or shape, making them highly versatile and customizable.

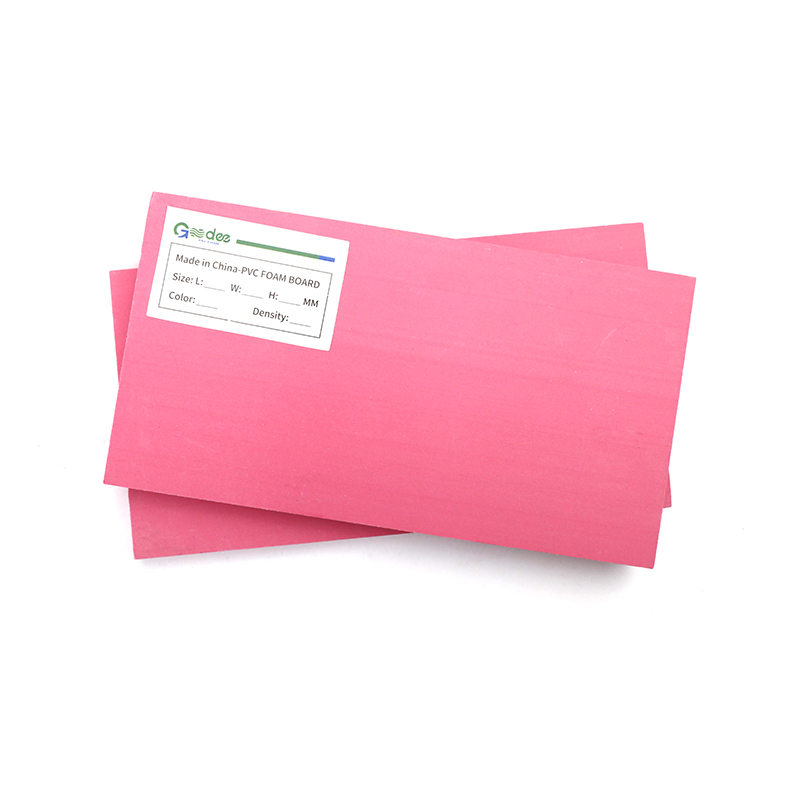

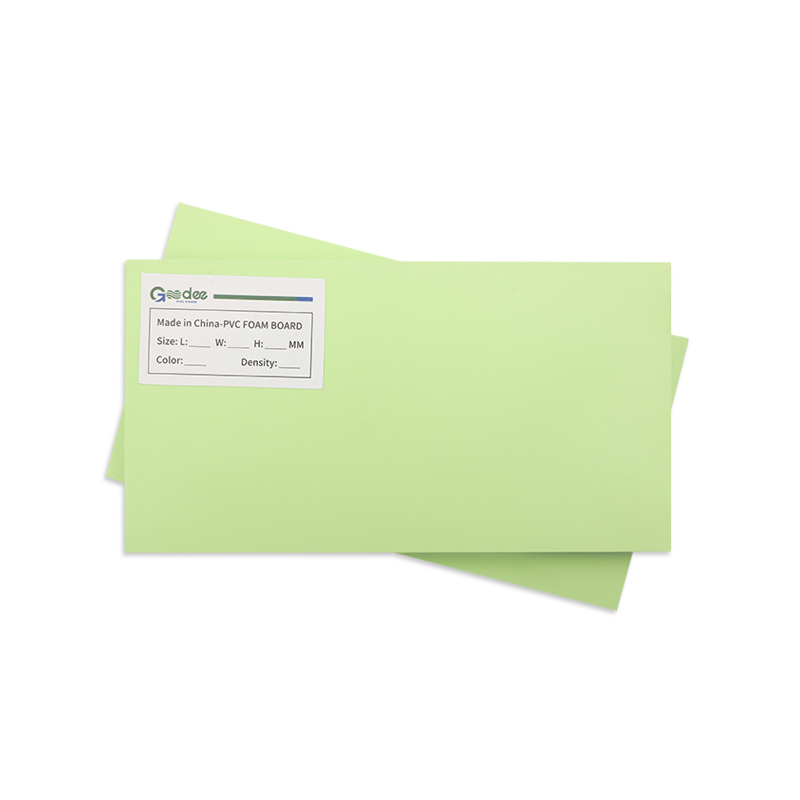

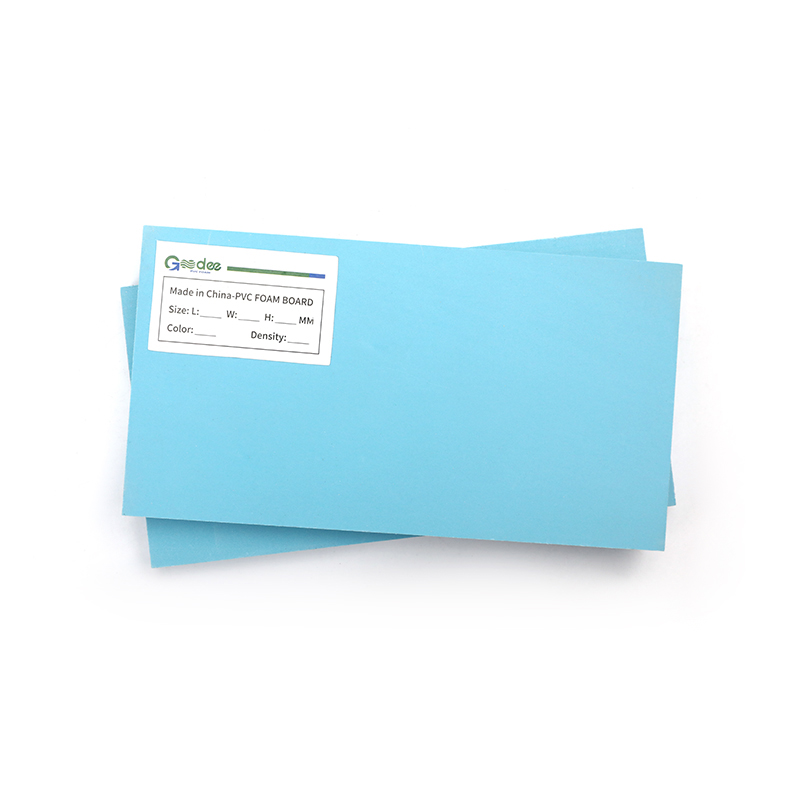

PVC boards for decorative panels are available in a range of colors, finishes, and textures. They can be printed, laminated, or coated with a film to give them a specific look and feel. Some of the popular finishes include glossy, matte, satin, and embossed.

PVC boards for decorative panels have several advantages over other materials like wood, metal, and glass. Some of these advantages include:

Durability - PVC boards are highly durable and resistant to weather, UV rays, and chemical exposure. They do not rot, warp, or crack, making them ideal for use in outdoor and high-traffic areas.

Lightweight - PVC boards are lightweight, making them easy to handle, transport, and install. They do not require heavy-duty equipment or specialized skills, making them a cost-effective option for DIY projects.

Low maintenance - PVC boards require minimal maintenance, and they can be easily cleaned with soap and water. They do not require painting or staining, reducing the overall cost of ownership.

Fire-resistant - PVC boards are fire-resistant and self-extinguishing, making them safe to use in areas with strict fire codes.

Cost-effective - PVC boards are cost-effective compared to other materials like wood, metal, and glass. They are also readily available and can be produced in large quantities, reducing lead times and costs.

Factory directl PVC board for decorative panels offer a cost-effective and customizable solution for a range of applications. They are highly durable, lightweight, and require minimal maintenance, making them an ideal choice for both residential and commercial use. With various sizes, thicknesses, colors, and finishes available, PVC boards offer endless possibilities for designers, architects, and DIY enthusiasts alike.

English

English Español

Español