PVC or polyvinyl chloride is a common plastic material that has versatile workability, great chemical resistance and waterproof properties. It is an excellent choice for a variety of applications, including inflatable products, protection covers, stationery and construction materials.

Flexible cabinet and interior 17mm PVC plastic sheets are a popular option for making durable, lightweight and non-toxic furniture.

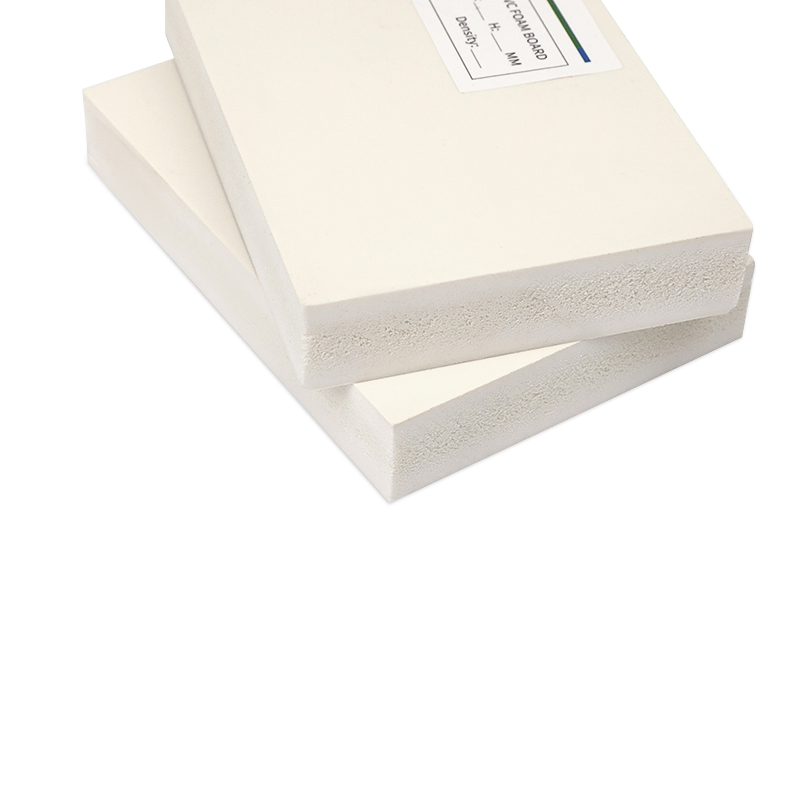

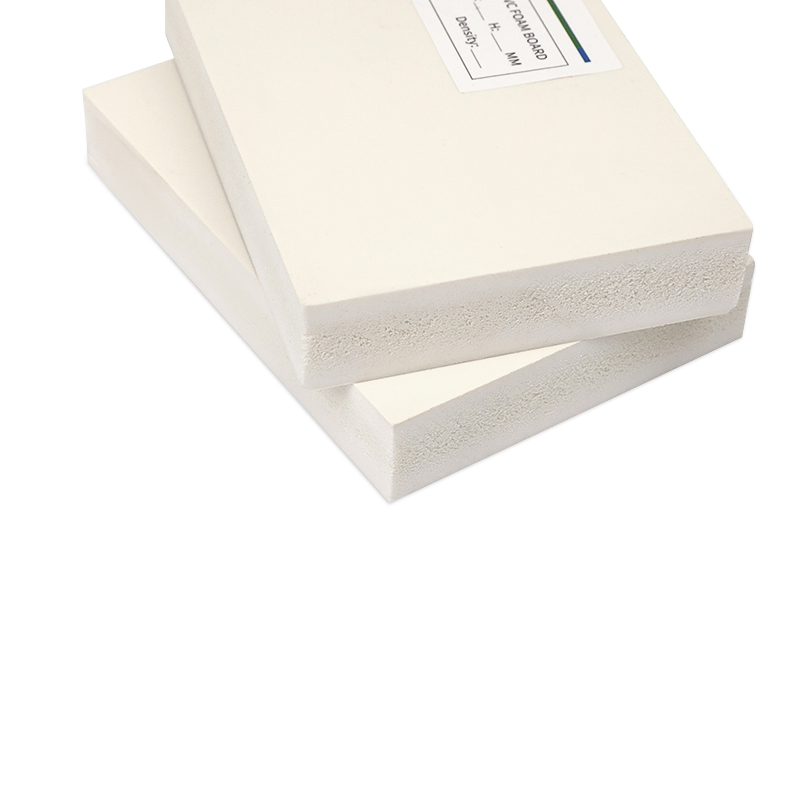

Thickness

PVC foam boards have a variety of uses in signage, store displays, screen printing, stage prop design, cabinetry and wood replacement. Their flexibility and durability make them an excellent choice for all types of projects.

Flexibility: Flexible cabinet and interior 17mm PVC plastic sheets can be bent up to 90 degrees without breaking, which makes them a great option for nuanced spaces such as designs with ridges. They are also resistant to moisture, UV light and termites.

Durability: Although they are susceptible to scratches, they can last a long time thanks to their superior elasticity and strength. They are also rot-proof, making them an excellent choice for kitchens.

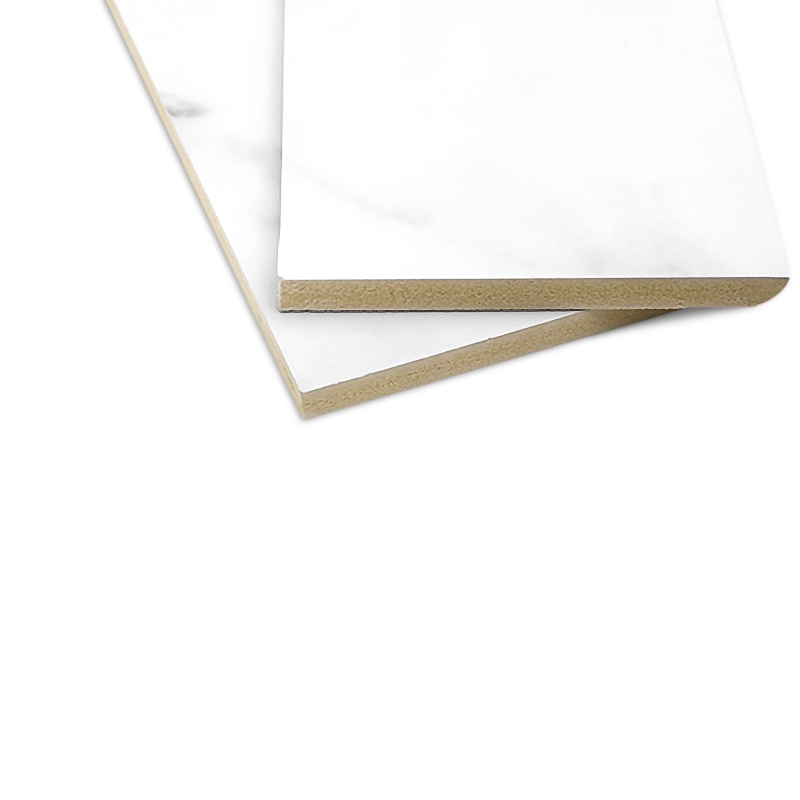

The thickest PVC laminates have a thickness of around 3mm and are available in matte or glossy finishes. These are highly recommended for modular kitchens as they are lightweight and strong enough to handle the rough use of the space. They are also resistant to corrosion, termites and heat.

Density

PVC is a rigid plastic that’s known for its lightweight and durability. It’s also easy to work with and can be painted or laminated. It’s also moisture-resistant, so it won’t warp or crack when exposed to water.

Another type of material used for cabinets is MDF. This material is durable and cost-effective, but it can be heavy and prone to warping and cracking. It can also emit formaldehyde if it’s not sealed properly.

Plywood is also a popular option for cabinets, but it’s more expensive and can be difficult to work with. It’s also more likely to break than MDF, and it can be prone to leaking formaldehyde if it’s exposed to water. Lastly, it’s less visually appealing than MDF and may not add as much value to your home. Ultimately, the best choice for your cabinet materials depends on your specific needs and preferences. Choosing the right material can make all the difference between creating beautiful and functional furniture that lasts for years to come.

Plasticizers

Plasticizers are chemicals that are added to polymers such as plastic and rubber to improve their flexibility, viscosity, softness, and friction level. They also make them easier to handle when being processed into end products.

Most PVC, for example, would be hard and rigid without the addition of plasticizers to make it softer and more flexible. This makes it ideal for shower curtains, clothing, bags, flexible plastic tubing, and electric wire insulation/coating.

Phthalate plasticizers are a type of chemical that are largely used in making PVC durable, flexible, weather-resistant, and compatible with other polymers. They are safe to use and are a popular choice for many products.

Phthalate plasticizers include di-2-ethylhexyl phthalate (DEHP), diisoheptyl phthalate (DIHP), and ditridecyl phthalate (DTDP). They are all derived from terephthalic acid, an organic compound. They are colorless, odorless, oily liquids that are slightly soluble in water. They have a high molecular weight and can resist heat. They are a popular choice for materials that require high-temperature stability.

English

English Español

Español