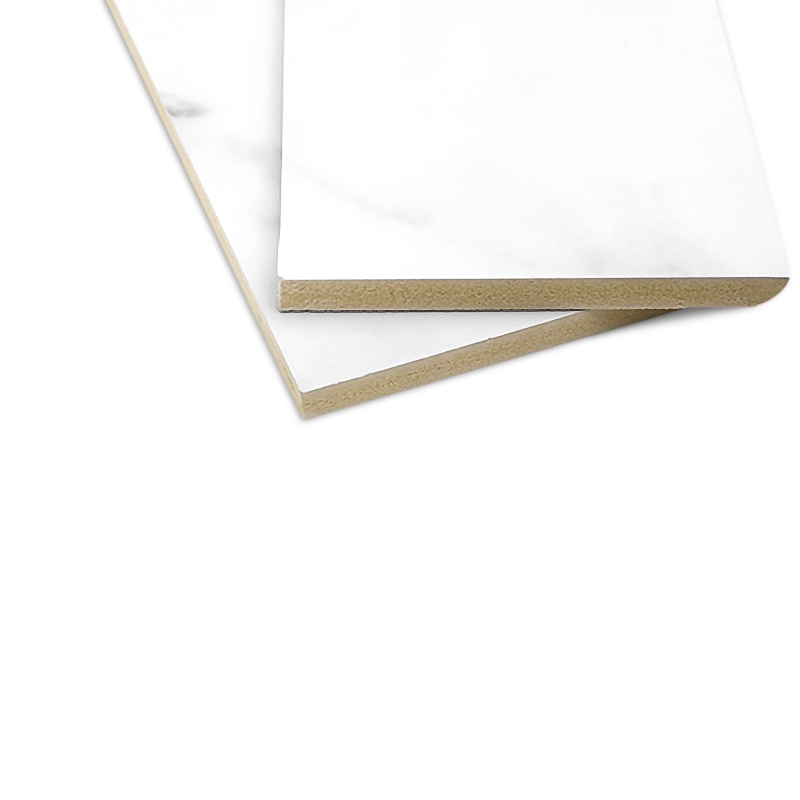

Working with 18mm glossy/matte laminated PVC celuka foam boards involves a few key steps to ensure clean cuts, precise shaping, and proper installation. These boards are commonly used for applications like signage, displays, and interior decoration due to their lightweight and durable properties. Here's a recommended process for cutting, shaping, and installing these boards:

Cutting:

Choose the Right Tools: For cutting, you'll need tools that can effectively handle PVC foam boards. Recommended tools include a circular saw with a fine-toothed carbide blade, a jigsaw with a fine-toothed blade, or a table saw with a carbide blade.

Marking: Use a straightedge and a pencil to mark the cutting lines accurately on the board's surface. Make sure your measurements are precise to avoid uneven cuts.

Cutting Process: Place the board on a stable work surface, ensuring that it's well-supported to prevent vibrations that could cause chipping. Cut slowly and steadily, allowing the blade to do the work. If using a jigsaw, choose a low-speed setting to avoid melting the PVC. If using a circular saw, make sure the blade's teeth are oriented to cut into the laminated side of the board to reduce chipping.

Smooth Edges: After cutting, the edges might be rough. You can use sandpaper or a file to smooth and bevel the edges for a clean finish.

Shaping:

Template and Marking: If you need to shape the board, create a template using paper or cardboard. Transfer the template's shape onto the board by marking the outline with a pencil or a light scoring cut.

Cutting/Shaping: Depending on the complexity of the shape, you can use tools like a jigsaw, a coping saw, a router with the appropriate bit, or even a sharp utility knife. Cut or shape gradually, following the marked lines. If using a router, use a low-speed setting and make shallow passes to prevent chipping.

Finishing: Just like with cutting, use sandpaper or a file to smooth and refine the edges and surfaces of the shaped area.

Installation:

Surface Preparation: Ensure the installation surface is clean, dry, and flat. If required, you can use adhesive or double-sided tape designed for PVC foam boards.

Adhesive: Apply an adhesive specifically formulated for PVC foam boards to the back of the board. Make sure to follow the manufacturer's instructions for application and drying time.

Mounting: Carefully position the board on the installation surface, aligning it properly. Press down firmly to ensure good adhesion. If using mechanical fasteners, make sure they are appropriate for PVC foam boards and spaced adequately to prevent warping.

Weight Distribution: For a temporary period during adhesive curing, you might need to place weights or use clamps to ensure even pressure across the board's surface.

Always remember to wear appropriate safety gear, such as eye protection and a dust mask, when working with PVC foam boards to avoid inhaling particles or getting debris in your eyes. It's also a good idea to test any cutting or shaping techniques on scrap pieces of the same material before working on your final project.

English

English Español

Español