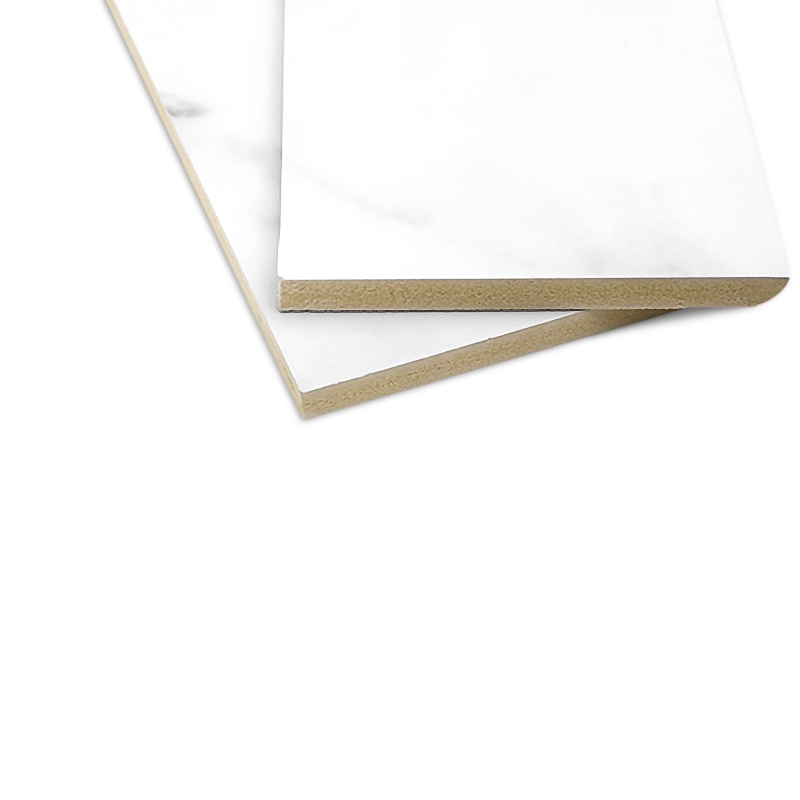

Wood fibers/sawdust: The primary component of WPC boards is wood fibers or sawdust obtained from various sources such as hardwoods, softwoods, or reclaimed wood. These fibers provide the natural appearance and texture of wood to the composite material.

Thermoplastic polymers: The wood fibers are mixed with thermoplastic polymers, which act as the binding agent and help provide durability and stability to the composite. Common thermoplastics used in WPC boards include polyethylene, polypropylene, and PVC.

Additives: Various additives are included in the mixture to enhance specific properties of the WPC boards. These additives can include coupling agents, colorants, UV stabilizers, flame retardants, lubricants, and other chemicals to improve the composite's performance and appearance.

Processing aids: During the manufacturing process, processing aids may be used to facilitate the mixing of the components and to improve the extrusion or molding process.

The combination of wood fibers and thermoplastic polymers in WPC boards results in a material that possesses the natural look and feel of wood while also offering increased strength, durability, resistance to moisture and insects, and reduced maintenance compared to traditional wood products. WPC boards find applications in various outdoor and indoor settings, such as decking, fencing, cladding, furniture, and more.

English

English Español

Español